Surface Mold Heating

Projects

Information

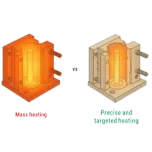

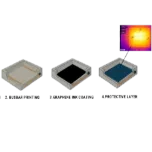

Our graphene-based heating layer transforms the way industrial molds are heated by applying energy only where it is needed: at the surface. Instead of heating the entire mold mass, this technology uses printed copper busbars and a graphene resistive layer integrated into the mold structure, protected by a durable top coating, to deliver rapid, uniform and precisely controlled heat. This targeted approach reduces energy consumption by up to twenty times compared to traditional systems, shortens ramp-up times, improves thermal homogeneity and enhances process stability. It is suitable for injection molding, composites and thermoforming and can be installed in new molds or retrofitted to existing tooling. By replacing bulky, slow oil or cartridge systems, it supports process electrification and decarbonization while increasing productivity.