Fine Solder Paste Printing for MicroLEDs

Projects

Information

This project explores advanced solder paste printing techniques to enable the assembly of ultra-miniature electronic components, such as microLEDs, which are essential for next-generation displays and optical devices.

Challenges with Traditional Screen Printing

Standard screen printing methods are limited in their ability to handle fine solder paste deposits due to the stencil aperture sizes and the maximum achievable print resolution. These limitations restrict the assembly of components smaller than the "0402" package size (0.4 mm x 0.2 mm), which is inadequate for emerging microLED technologies.

Advantage of Gravure Offset Printing

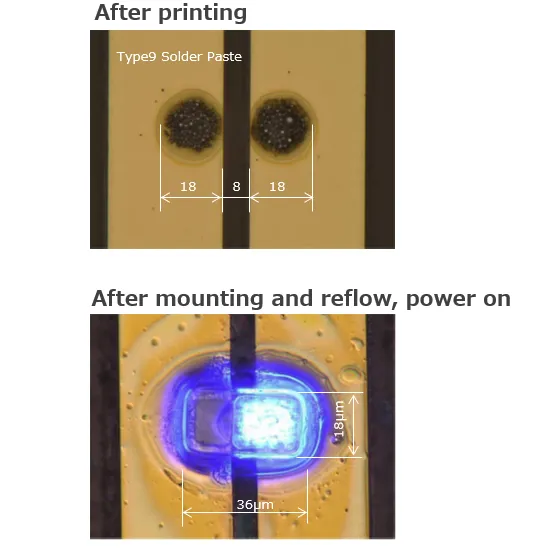

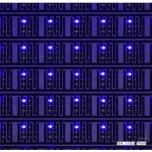

Gravure offset printing offers a promising alternative by achieving higher resolution and precision in solder paste deposition. Komori-Seria has demonstrated the capability to print solder pads with diameters as small as 6 µm on wafers with a pitch of 30 µm, resulting in microbumps that reflow to approximately 15 µm in diameter. This level of precision supports the assembly of microLEDs with dimensions as small as 30 µm x 50 µm or 30 µm x 80 µm, which is crucial for the development of high-density microLED displays .

Strategic Focus on MicroLEDs

MicroLEDs are among the smallest and most visually impactful electronic components, emitting light and serving as a clear demonstration of advanced manufacturing capabilities. Komori-Seria is actively pursuing the development of soldering technologies for microLEDs using gravure offset printing to showcase their technical expertise and to meet the growing demand for high-resolution display technologies.

Conclusion

By leveraging gravure offset printing, this project aims to overcome the limitations of traditional solder paste printing methods, enabling the assembly of ultra-small components like microLEDs. This advancement is poised to play a significant role in the evolution of next-generation display technologies.