Development of Water-Soluble Lift-Off Process for Chip Resistors

Projects

Information

This project aims to replace the laser trimming method used in the manufacturing of chip resistors—a key surface-mount technology (SMT) component—with a more efficient, high-throughput process based on gravure offset printing.

Currently, the internal resistive patterns of chip resistors are created via screen printing, but this method lacks the resolution needed for fine features. As a result, laser trimming is employed to finely adjust resistance values. However, laser trimming is slow and reduces productivity.

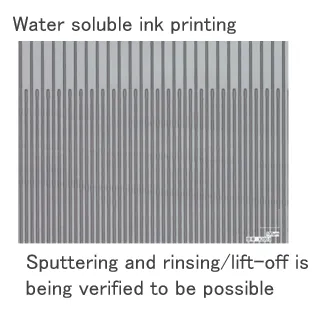

To address this, Komori-Seria has received a request from A Taiwanese manufacturers to develop a gravure offset-based process that can directly print fine resistive patterns, eliminating the need for laser trimming. A water-soluble lift-off process is being developed as part of this solution, enabling precise pattern formation with improved efficiency and environmental compatibility.

This shift promises:

Higher productivity by removing the laser trimming step,

Finer pattern resolution using gravure offset,

Improved environmental performance through water-soluble materials.