Copper Paste Development for RDL (Redistribution Layer) Printing

Projects

Information

This project focuses on developing a copper paste suitable for printing redistribution layers (RDLs), which connect integrated circuit (IC) chips to motherboards. Traditionally, RDLs are fabricated using photolithography, a process that is both costly and environmentally unfriendly due to material and liquid waste.

In response to industry demand, Komori-Seria is collaborating with Sakata Inx to create a cost-effective and eco-friendly copper paste alternative. Copper is specifically chosen over silver due to its superior resistance to electrochemical migration—a failure mode where, under high voltage, temperature, and humidity, dendrites form and short adjacent wires. Silver is more susceptible to this issue, making copper a more reliable material for fine-pitch wiring.

Key Achievements and Specifications:

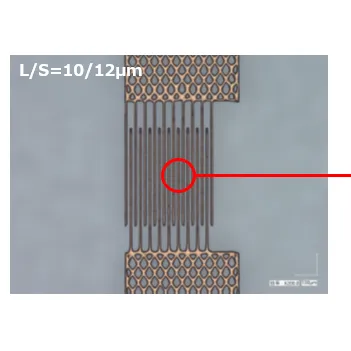

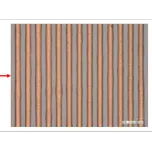

Printing Resolution: Achieved fine-line printing at L/S = 10 µm / 12 µm (line and space).

Migration Resistance: Successfully passed migration tests, validating copper’s suitability.

Volume Resistivity: 1.3 × 10⁻⁵ Ω·cm, indicating good conductivity.

Firing Conditions: 150°C for 30 minutes under formic acid atmosphere.

Remaining challenges include improving adhesion of the copper paste, but ongoing development is progressing toward a viable alternative to conventional RDL fabrication.