Printed Force Sensor

Products

Information

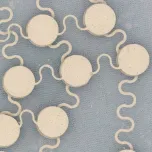

The Revolution in Flexible Printed Force Sensing Technology

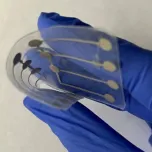

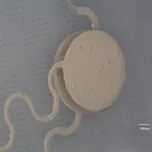

At Silicon Austria Labs, we develop printed force sensors that offer a range of compelling advantages for various applications and industries. These sensors can be produced in virtually any shape or size, over large areas and together with the interconnections, providing immense flexibility in design. This allows for seamless integration into a wide range of different products, from intricate medical wearables to large-scale industrial machinery.

Additive manufacturing is a cost-effective solution for fabricating electronic components. The processes require less raw materials and resources, reducing waste generation and energy costs. Printing processes also facilitate mass production, which can further mitigate environmental impact and reduce the costs.

The flexibility of these sensors and their compatibility with various substrates mean they can be readily integrated with other printed electronic elements, such as circuits and antennas, to create more complex sensor systems within a single, streamlined unit. Our cutting-edge sensors are designed to transform forces into actionable data with high precision and flexibility.

Benefits & Advantages

- Custom force sensing solutions – whether you are looking for small runs for prototyping purposes or large-scale production. A wide range of specifications, size, shape and accuracy are possible.

- More sustainable – additive manufacturing, with lowest waste generation possible. Wide range of materials and functional inks lead to low ecological footprint.

- Easily embedded in your product – Designed for compatibility, our sensors integrate smoothly with a variety of systems, making them ideal for a wide range of applications and accelerating product development cycles.

Further information can be found among the Documents.