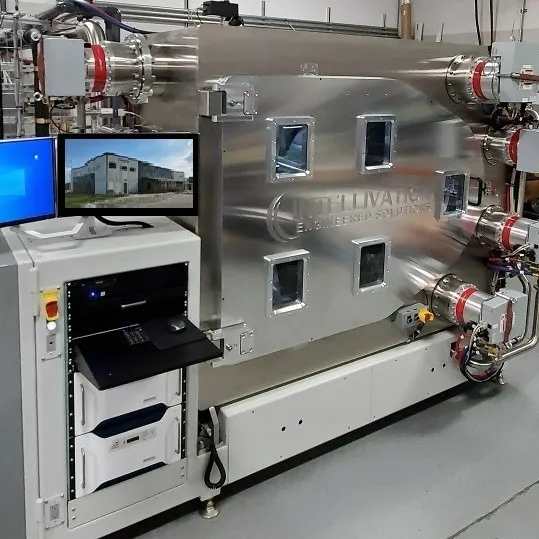

R2R Series Vacuum Web Coating Systems

Products

Information

The INTELLIVATION R2R Series roll to roll web coating systems feature substrate pretreatment, four to five configurable process zones, a temperature controlled coating drum and a state of the art control system. Process zones can be configured for planar sputtering magnetrons, rotary sputter magnetrons, evaporation (thermal or e-beam) and plasma surface treatments like glow discharge and anode layer ion source. Designed for roll to roll web coating and roll to roll processing of flexible substrates including metal foils, polymer webs, textiles, flexible glass, and flexible ceramics, with coated widths up to 500mm. The R2R series has proven itself in such applications as metallization, security films, optical coatings, flexible electronics, barrier films, medical devices, batteries and other leading edge roll to roll technologies.

We invite you to come to our fully equipped R2R application development laboratory and try your product idea on our R2R coater.

The powerful yet intuitive control system includes data logging and recipe based processing. A suite of optional in-situ metrology techniques provide for quality assurance of films and for rapid development cycles. The compact design of the R2R series maximizes efficiency by delivering high throughput in a small footprint. Cost of ownership is further reduced through excellent ease of access for operation and maintenance and reduced utility costs as a result of a proprietary coating drum roller design.