CondAlign

Silver

Information

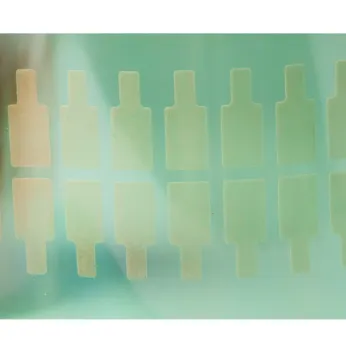

CondAlign provides groundbreaking conductive films for bonding electronics and thermal transfer

CondAlign develops, manufactures, and delivers ground-breaking material technologies that empower our customers to create innovative, high-performing, and more sustainable products for the future—reducing costs, conserving energy, and minimizing the use of precious resources.

Our vision at CondAlign is to become the preferred supplier of sustainable, functional films that enable the development of cutting-edge, environmentally friendly products across various industries. We are committed to driving innovation while contributing to a greener, more resource-efficient future.

Topic/Technology

AR/VRFlexible DisplaysFlexible Hybrid ElectronicsWearable ElectronicsmicroLEDsPrinted ElectronicsR2RTransparent Conductive FilmsSkin PatchesWearable Sensors