Polycrystalline Diamond Powder

Materials

Information

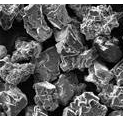

"Product performance:Polycrystalline diamond as compared to synthetic monocrystalline diamond provides better surface finishes and higher removal rates for metallographic specimen preparation. The features and advantages of polycrystalline diamond include the following:

Higher cutting rates

Very uniform surface finish

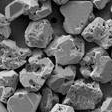

More uniform particle size distribution

Higher removal rates (self sharpening abrasives)

Harder/tougher particles

Blocky shape

Hexagonal microcrystallites (equally hard in all directions)

Extremely rough surface (more cutting points)

Surface area greater than monocrystalline diamond

No abrasion-resistant directionality (abrasion independent of particle orientation)

Hold Diamond have 3 kinds of polycrystalline diamond ,HDPG-10 has the highest friability, and HDPG-30 has the highest toughness.

"

Tools - abrasives - chemicals

Tools and abrasives