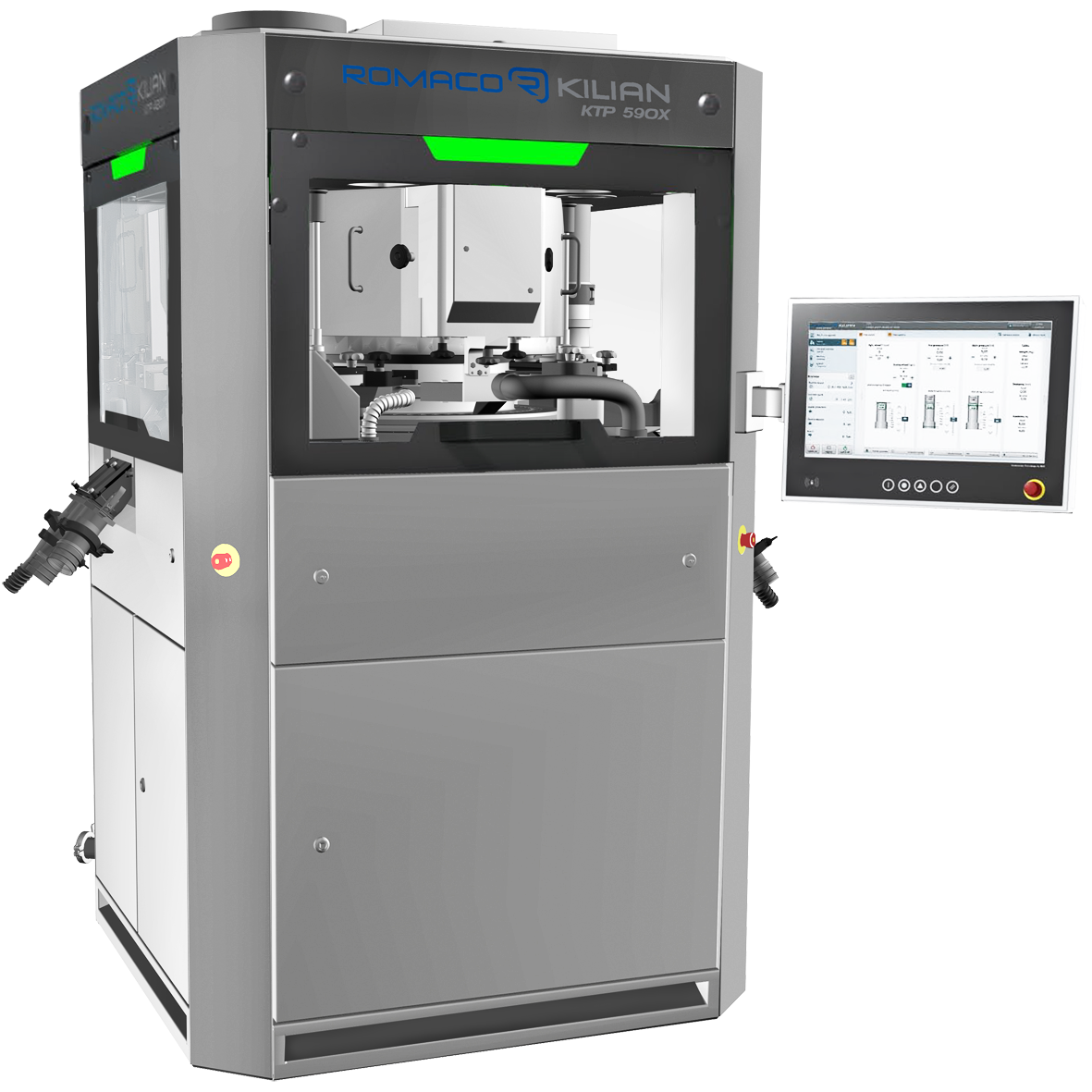

Tablet press KTP 590X from Romaco Kilian

Process Equipment

Information

The KTP 590X is a single sided, versatile, high speed tableting machine. Optimised for fast change over between bi- and monolayer tablet mode and for high speed effervescent tablet production. The machine can be equipped with up to 3 sets of compression rollers for best performance, even for mono-layer application.

It is available in the following configurations:

Mono- & bi-layer tablet production

Bi-layer production

Mono-layer production

Cool

Effective cooling of the process area to below 30 °C – ideal for processing temperature sensitive formulations such as Ibuprofen

Special compression rollers, bolts and bearings ensure lowest possible friction

Efficient cooling of the torque drive and the V-ring seal (for the die table)

Fast

Up to 510,000 tabs/h as mono machine

Up to 510,000 tabs/h also as bi-layer machine

Excellent performance with challenging high volume products such as Metformin and Amlodipin

No conversion of compression stations required for changing the machine configuration

Quick product and format changes: tablet chute and fill shoe can be swung out – no tedious readjustments

Few product contact parts: minimal cleaning effort

2 full size fill shoes

Clean

Optimal hygienic design

Hermetical separation between compaction and service area

Patented closed punch bellows to prevent tablet contamination