Shell PIPA, a Pre-Incident Planning tool

Services and Technologies

Information

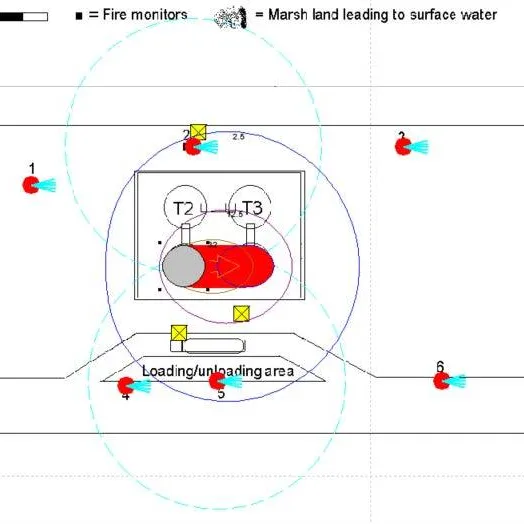

Shell PIPA quickly and easily provides fire chiefs, response teams, and plant operators with hazard consequence assessment information, to assist them in the development of emergency response plans and the specification of fire protection requirements.

Easy and simple to use, the software has a variety of outputs from simple graphs showing the size of hazard consequences to full emergency response plans including hazards, protection requirements, and justifications.

Uses and applications

- Assists in the development of emergency response plans

- Cost-effective screening of plant design options, comparing concepts and assessing modifications

- Quickly reviews and sets separation distances between plant, equipment, workers and members of the public

- Rapid identification of the most serious potential consequences

- Specifies fire protection requirements

Key benefits

- Gives easy access to Shell’s state-of-the-art consequence modelling suite

- Provides fast, reliable and exact prediction of the consequences of potential releases and fires

- Assists in rapid development of appropriate emergency response plans

- Enables cost-effective plant design e.g. fire protection measures

- Enables fire chiefs to quickly run ‘what if’ weather variations on pre-programmed scenarios at real incidents