DCU - control logic programming and alarming

Products

Information

DCU supports complex control logic programming, scripting, and scheduling for tasks such as: energizing solenoid valves, validation and calibration sequences, purge, blowback, sample handling, flow, PID (Proportional Integral Derivative Gain) control loops, time-sharing and stream switching, trip point monitoring and condition-based alarms. This can potentially save a lot of time typically spent programming PLCs, as DCU is a software based controller and can be reused for future applications. All control commands can be executed using Windows Task Scheduler, to automatically initiate calibrations, perform blow-back or switch the analyzer stream.

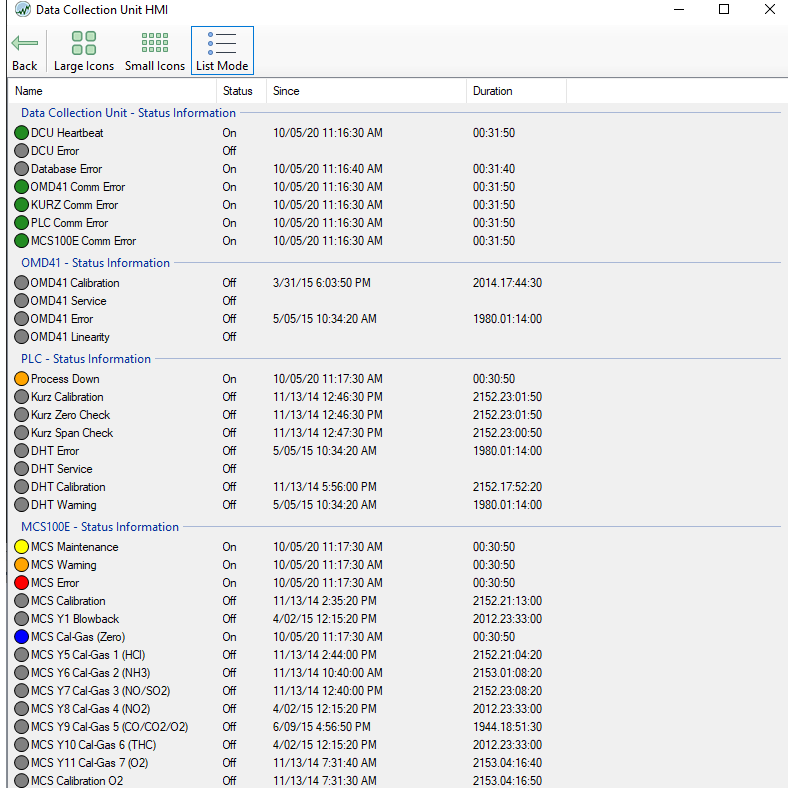

Additional diagnostic information can be obtained from analyzers to monitor device health status and performance, generate alarms and notifications, trigger preventative maintenance procedures and reduce downtime. The curve fitting algorithm is used to detect when the actual response value during validation has approached the expected set point, calculate the drift, and proceed to the next step. This allows gas cylinders to last longer and saves time.