Optimizing industrial welding with AI and robotics

AI Projects

Information

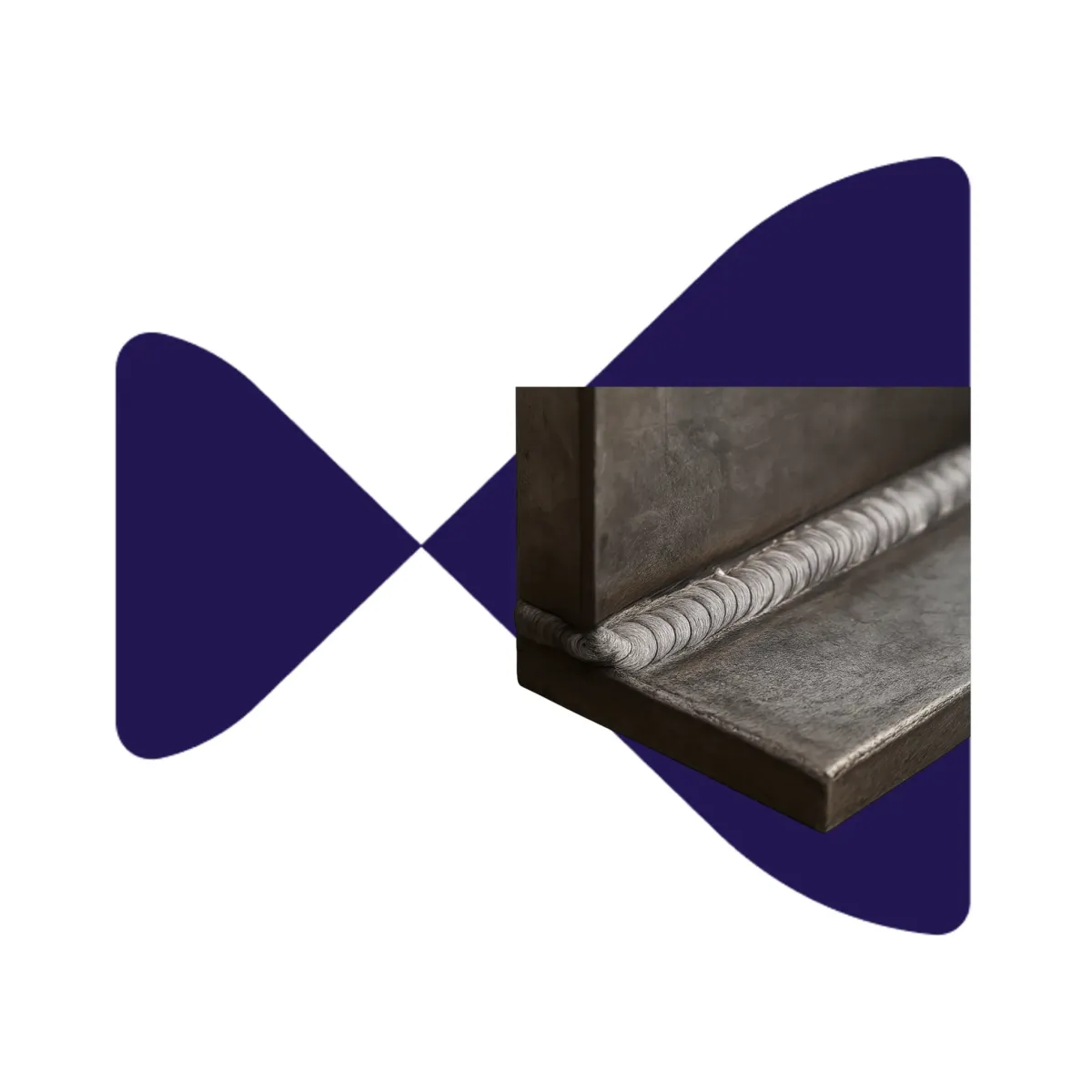

Metal Marquis, a leader in the metallurgical and mining industries, faced a major challenge: automating the welding of unique and complex metal parts while maintaining an exceptional level of precision. Unlike large-scale production lines, where identical parts follow the same welding program, the parts handled by Metal Marquis vary widely in shape, size, and degree of wear. The company needed a solution that would allow a robot to dynamically adapt to the specific characteristics of each part - without requiring laborious manual reprogramming.

An intelligent robot that adapts in real time

Explorai developed a solution combining artificial intelligence and advanced robotics to give the welding robot the ability to analyze each part and adjust itself autonomously. Relying on advanced 3D modeling, the system identifies an optimized welding path for the targeted area. The planning algorithm takes into account the geometry of the part, the robot's physical constraints, and potential collision risks to define the ideal trajectory. Real-time path adjustments ensure a consistent weld, delivering both strength and high-quality results.

"A dedicated, innovative and multidisciplinary team. ExplorAi, accompanies us very well in our project, they rise to the challenges and find solutions. They have a very good project follow-up structure and are open to adapting as the project progresses. I recommend them! "

- Patrick Perreault - President, Métal Marquis